Reci® CO₂ Laser Tube – W Series, 75W-150W Rated Power

Reci® CO₂ Laser Tube – W Series, 75W-150W Rated Power - W1 이월 주문되었으며 재고가 확보되는 즉시 배송됩니다.

🆕 New Product Line: Reci® Co2 Laser Tube!

🚨 Important: Reci® Co2 Laser Tubes are fragile and

non-returnable. Please contact us at lou.d@americanphotonics.com

before purchasing to ensure the product meets your needs.

🌍 Customs & Shipping: Orders shipped from our China

Warehouse may incur customs fees. Be prepared for additional charges based on local regulations. 📦✈️

Disclaimer: Reci® is a registered trademark and is not associated with

American Photonics.

Delivery details to be confirmed via sales email. 📧

Thank you for choosing us! 🌟

Care information

Care information

High care information about CO2 laser lenses, fiber laser protective windows, and

fiber laser lenses is essential to ensure the optimal performance and longevity

of these critical components in laser systems. Here are some key points to consider:

CO2 Laser Lenses:

Cleaning:

Regularly clean CO2 laser lenses to remove dust, debris, and residue. Use a

soft, lint-free cloth or lens cleaning tissue. Avoid using abrasive materials

that may scratch the lens.

Handling:

Always handle CO2 lenses with clean hands or lint-free gloves to avoid transferring oils or contaminants onto the lens surface.

Storage:

Store lenses in a clean, dry, and dust-free environment to prevent damage and

maintain their integrity.

Alignment:

Properly align CO2 lenses within the laser system to ensure efficient laser

beam delivery and focus.

Inspection:

Regularly inspect lenses for signs of damage, scratches, or deterioration.

Replace any damaged or worn lenses promptly.

Fiber

Laser Protective Windows:

Cleaning:

Clean fiber laser protective windows with care to avoid scratches. Use a gentle

cleaning solution and a soft, lint-free cloth.

Protection:

Keep protective windows in place when the laser system is not in use to prevent

contamination and damage.

Replacement:

If protective windows become damaged, replace them immediately to maintain

laser system safety and performance.

Fiber Laser Lenses:

Cleaning:

Clean fiber laser lenses carefully to prevent damage. Use a lens cleaning

solution and a soft, lint-free cloth or lens tissue.

Handling:

Handle fiber laser lenses with care to avoid fingerprints, oils, or scratches

on the lens surface.

Alignment:

Properly align fiber laser lenses to ensure accurate laser beam focusing and

efficient performance.

Inspection:

Regularly inspect fiber laser lenses for signs of wear, damage, or contamination. Replace any compromised lenses promptly.

Environmental Considerations: Be mindful of environmental factors such as temperature and

humidity, as extreme conditions may affect lens performance.

Overall,

maintaining high care and attention to detail when handling, cleaning, and

storing CO2 laser lenses, fiber laser protective windows, and fiber laser

lenses will enhance their longevity and contribute to the smooth and reliable

operation of your laser systems. Always follow the manufacturer's guidelines

and best practices for each specific component to ensure optimal results.

Delivery and Shipping

Delivery and Shipping

Order Processing: Allow 2-5 business days for order handling.

Shipping Duration: Estimated at 30-45 days from China. Delays can occur, your patience is appreciated.

Shipping Terms: Orders ship EXW (Ex Works). You're responsible for loading, transportation, and customs. Recommend a freight forwarder for smooth handling.

Customs and Fees: Buyer bears customs fees and import taxes. Check local regulations for details.

Receipt & Inspection: Inspect goods on arrival. Report damages to your shipper.

Returns: Due to fragility and shipping logistics, Reci Laser Tubes are non-returnable.

Contact: For issues or queries, reach out to lou.d@americanphotonics.com.

Disclaimer: Reci® is a trademark not affiliated with American Photonics.

By purchasing, you agree to these terms.

Thank you for choosing our products.

Now in the third generation of development, Reci® W Series CO₂ Laser Tubes have become known for excellent performance and consistency.

✅Advanced radioactive materials coated lenses

✅Distinctive metal-glass sintering techniques

✅Long life – up to 10,000 hours with relatively low yearly maintenance

✅Great for engraving acrylic, cardboard, ceramics, glass, leather, paper, stone, wood, etc.

📦Please allow 1 week for delivery for W1, W2, W4, & W6

W-Series Parameters

|

Model |

Rated Power |

Peak Power |

Length |

Diameter |

Catalytic |

Warranty |

Triggering Voltage |

Rec'd Current |

|

W1 |

75 |

90 |

1110 |

80 |

yes |

540 days |

19kV |

22mA |

|

W2 |

90 |

100 |

1250 |

80 |

yes |

540 days |

19kV |

24mA |

|

W4 |

100 |

130 |

1400 |

80 |

yes |

540 days |

24kV |

26mA |

|

W6 |

130 |

160 |

1650 |

80 |

yes |

360 days |

28kV |

28mA |

|

W8 |

150 |

180 |

1850 |

90 |

yes |

360 days |

30kV |

28mA |

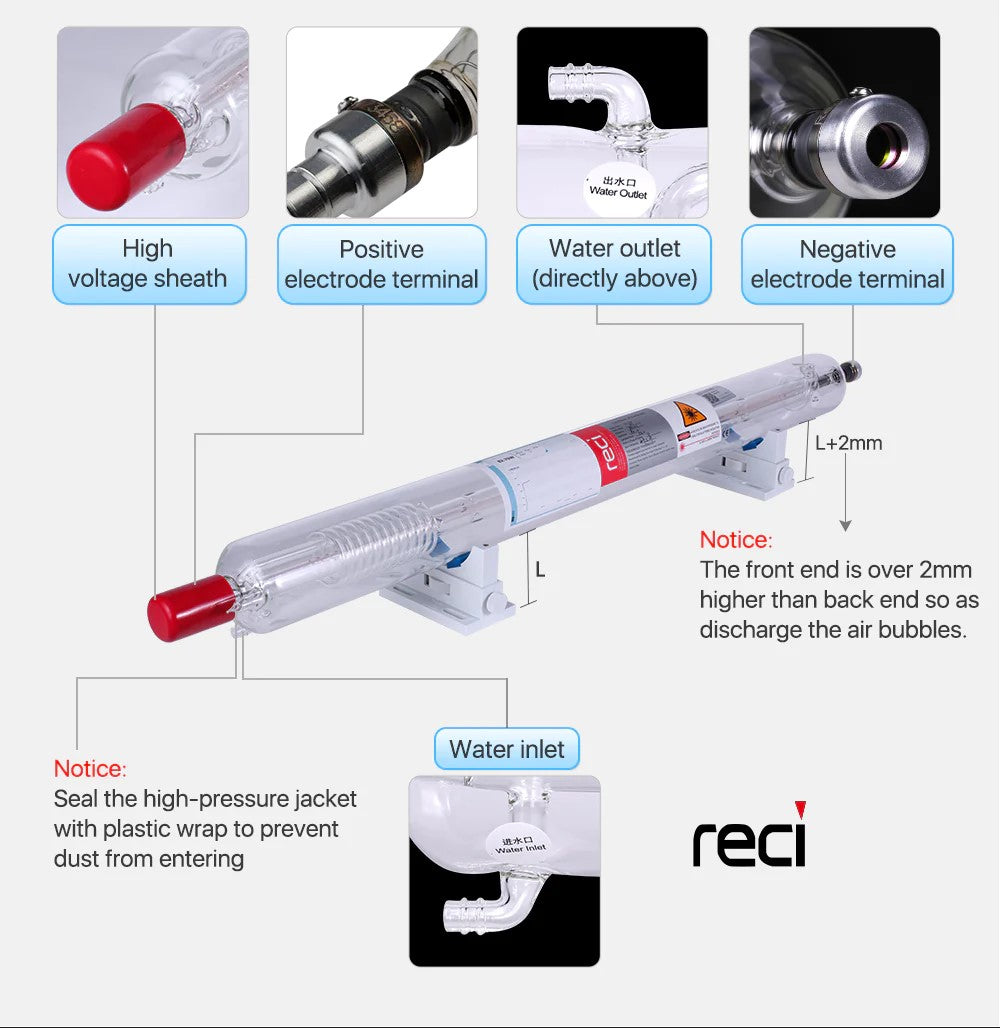

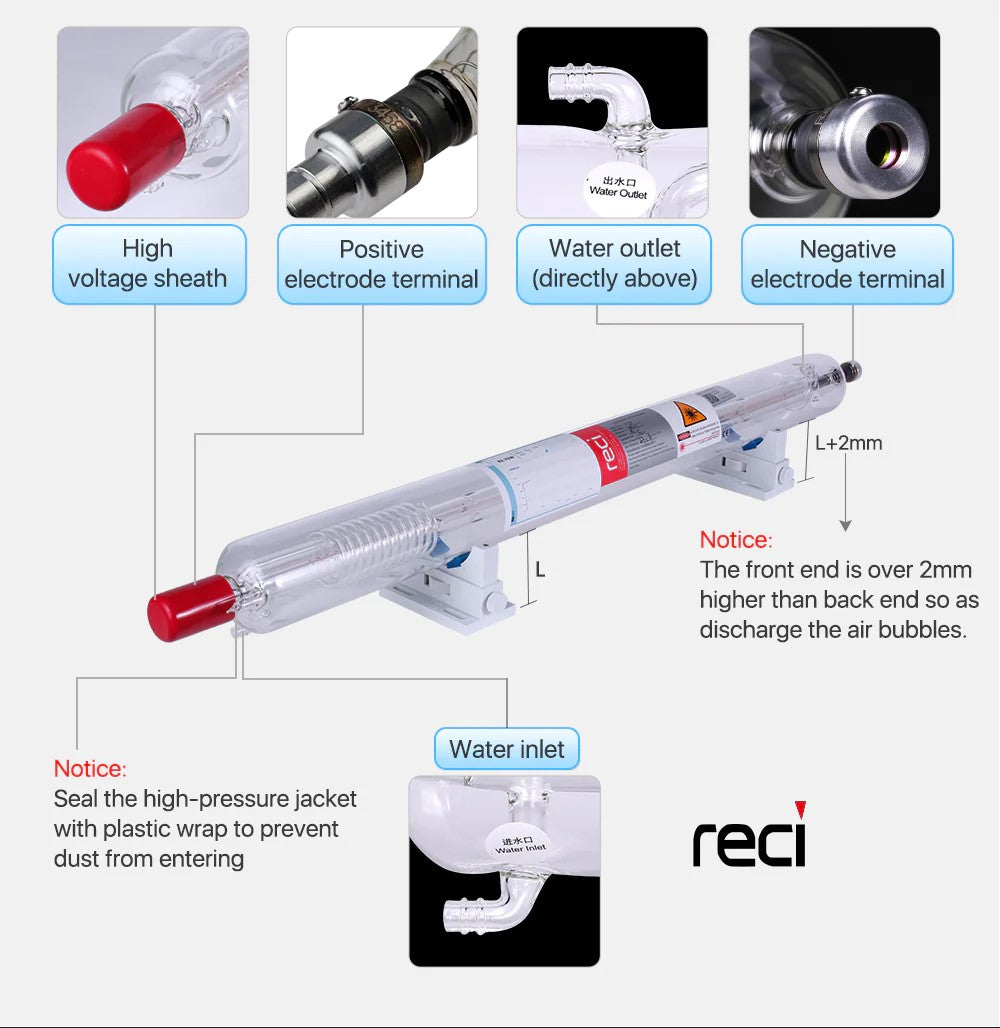

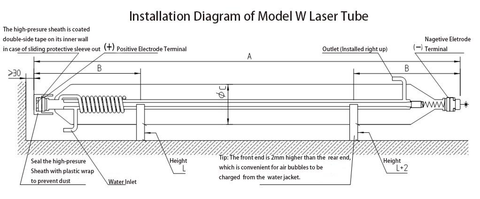

Installation and Usage

- Connect the positive and negative of laser tube with power supply, and insulate it properly.

- Use the 4mm soft pipe, connect the water inlet and outlet of the laser tube.

- Turn on the water circulation, so that the cooling water flows through the entire water line and avoid any air bubbles. Otherwise there is a risk of burst pipes.

- Start inching, and then the laser tube will emit the laser light. Adjust the position of the laser tube so that the spot hits in the middle of the reflective mirror.

- If the light is not correct, please adjust the position of the laser lens until light adjustment is complete.

- When the laser tube is first working, please generally adjust 50%-60% of the power to work.

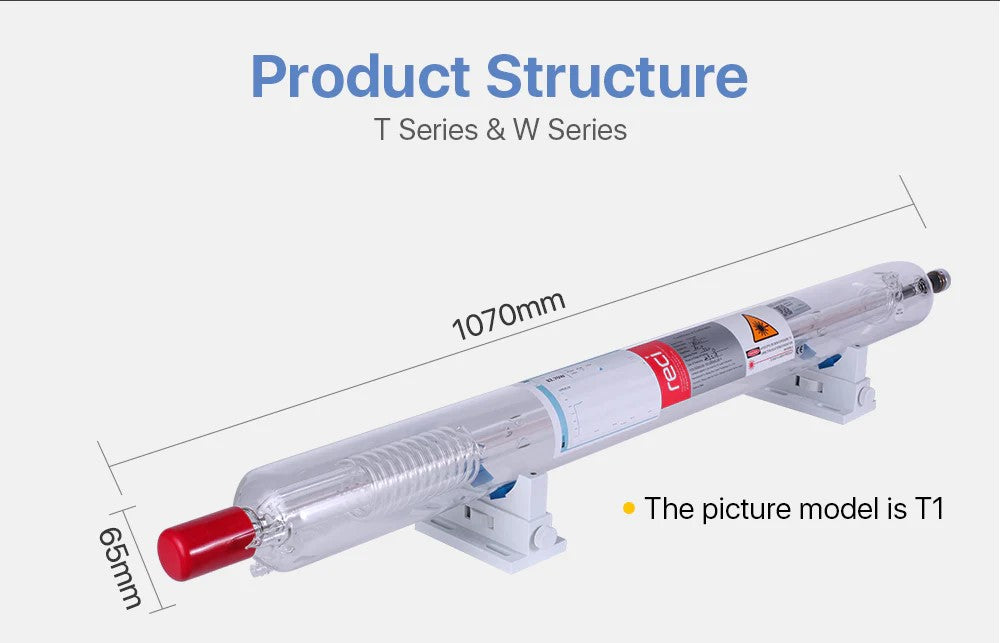

Length A: Length of the tube

Length B: Recommended distance from the ends of laser tube to pipe rack

Length C: Diameter of laser tube

Unit:mm

FAQs

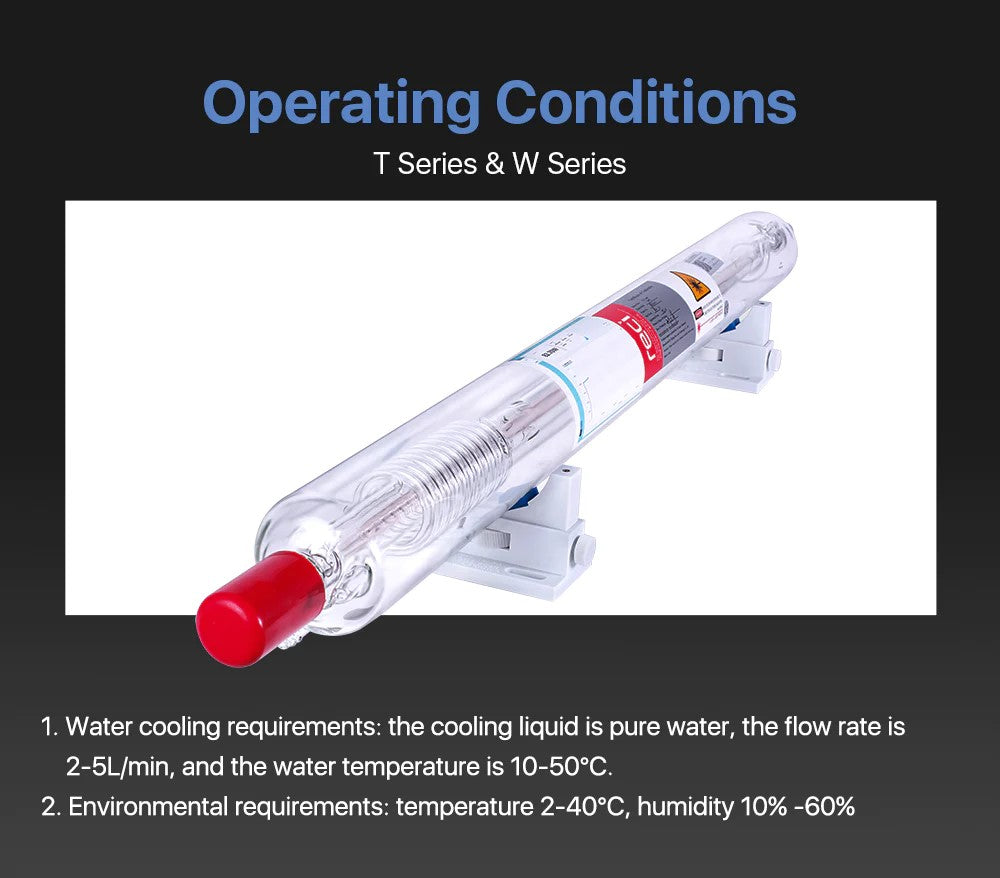

Q: What are the operating conditions of the laser tube?

A: Water cooling: it is recommended that the coolant be pure water, with a flow rate of 2-5 liters per minute and a standard water temperature of 10 ℃-50 ℃. Operating environment: temperature 2-40 ℃, humidity 10% - 60%.

Q: How do I match the DY power supply for the RECI W series laser tubes?

A: We recommend the W1 laser tube to work with DY10 power supply, W2 laser tube to work with DY13 power supply, and W4,W6,W8 laser tubes to work with DY20 power supply.

Q: Is it difficult to deal with after-sales problems?

A: It's easy to deal with after-sales problems with us. Please contact with us directly.

Normally, it will take 1-2 working days to resend the replacement for the shipping damage and product fault (not including improper operation) after the problem was confirmed.

Q: Why can't my tube reach the high power listed?

A: We are able to guarantee the rated/agreement power, but we can't guarantee the peak power. The actual power of each tube is between rated power and peak power.

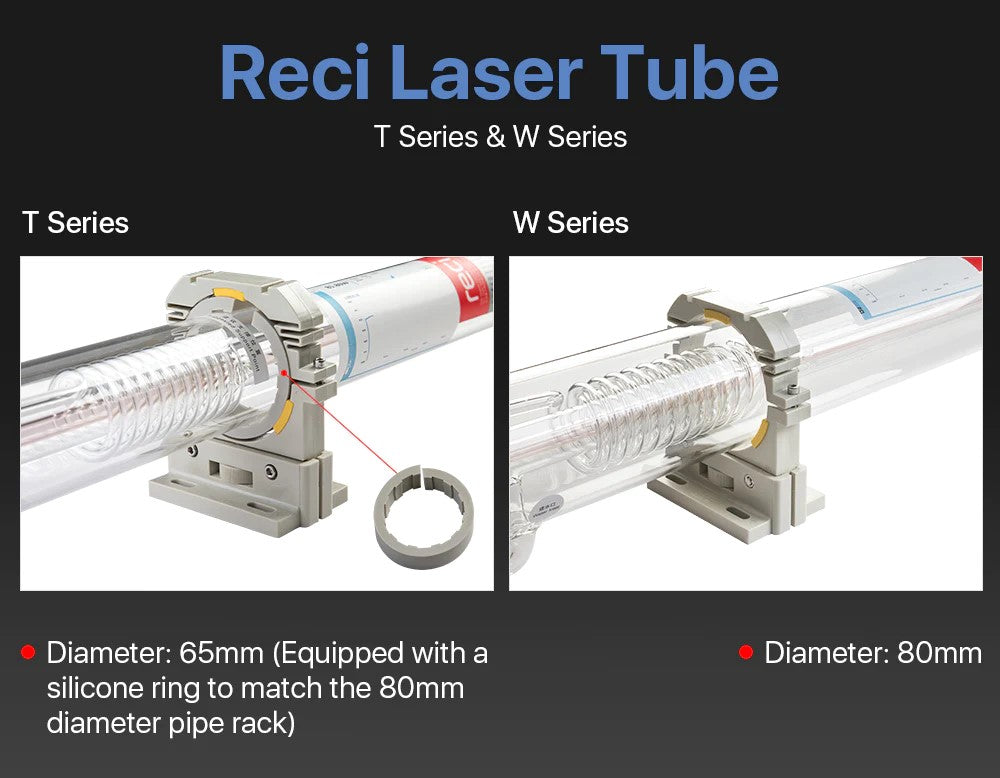

Q: What's the difference between W and T series?

A: T and W series tubes are produced using the same process. The W series began production in 2008, and the T series is a more affordable series launched in 2019. The diameter of W series is larger than that of T series, and the warranty time is slightly longer than that of T series.

Q: Which is the most common power in the marking machine?

A: The common power ratings are 90W, 100W and 130W in the machine. The models are the W2, W4, W6 & T2, T4, T6 respectively.

AmericanPhotonics: Radiating Excellence

Experience unmatched precision and quality with our American-made infrared laser optics.

Discover personalized service that exceeds expectations.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

KeyFeatures of Our Products: