American Photonics customer service and/or sales team receive daily questions about what lens to buy for my Co2 Laser machine.

We do manufacture more than 4000 part number for Co2 Laser Lens Low Power ( Engraving and Marking).

The best way to know what lens or mirrors you need is to measure the ones you have installed in your machine.

For a fast answer about BOSS LASER here is the 2 links where you can buy direct from our webstore 2 lens for your Boss Laser:

The 50.8mm (2.0) is the most popular Focal length

The 101.6mm(4.0") is the 2nd best seller focal length

American Photonics (APC) offer many different focal lengths 1.5", 2.0", 2.5", 3.0", 4.0", 5.0", 7.5"

Each focal length for different kinds of applications, Lets give some examples:

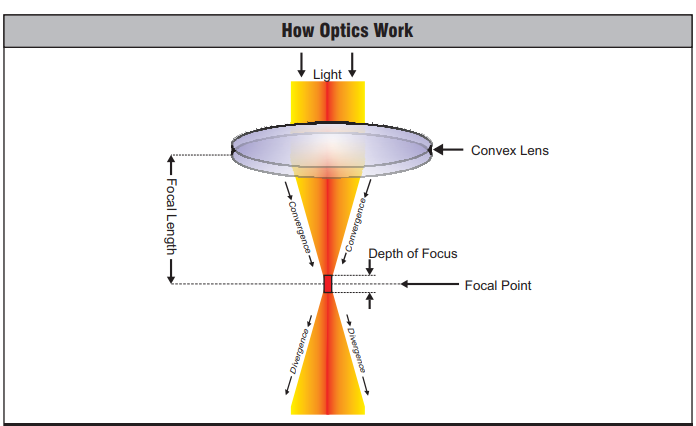

1.5” Lens has been designed for the very high resolution engraving and etching of extremely small fonts and photos. The 1.5” tolerance is low and cannot handle much deviation from the focus point. Because of high divergence it will not be a good thick cutting lens on materials thicknesses over 0.2” or 5,08mm.

What it does: 1.5” lens produces a small, focused beam or spot. Depending on the type of material being processed, and the desired effect, the effective spot size produced by this option is about 40% smaller then the 2.0 inch focusing lens allowing for higher details and quality during the engraving and marking process.

The 2.0” inch lens provides a combination of amazing engraving and marking details combined with a very good cutting ability. It is because of this that the 2.0” lens is the most general lens it is the best seller and most popular.

What it does: This is the all purpose lens that will produce high quality engraving and marking as well as consistent cutting, up to 1/2” (12,7mm) or more in thickness depending on the type of material being processed. If there is a question on what lens to use this will be the most practical choice.

The 2.5” inch lens provides good engraving detail though not as good as the shorter lenses. This is the lens kit used when clearance or tolerance becomes an issue. This lens has a longer focal length and great tolerance making it excellent for cutting thick materials up to 5/8” (15,875mm) depending on the material. This lens also gives you an additional 1/2” (12,7mm) clearance over the standard 2.0” however it also reduces your total Z axis (table height) by that same 1/2” (12,7mm).

What it does: This is the best lens for thick, consistent straight edge cutting when clearance and tolerance becomes an issue, while still providing good quality engraving and marking. Cutting with this lens up to 3/4” (19,5mm) in thickness depending on the type of material being processed.

The 3.0 inch lens provides good detail. This is the lens used when clearance or tolerance becomes an issue; this lens gives you an additional 1” (25,4mm) clearance over the standard 2.0” lens, but still maintains good engraving quality. This lens has a longer focal length and a greater tolerance making it excellent for cutting thick materials up to 3/4” (19,5mm) or more depending on the material.

What it does: This is the best lens for thick consistent straight edge cutting when clearance and tolerance becomes an issue, while still providing good quality engraving and marking. Cutting with this lens up to 3/4” (19,5mm) or more in thickness depending on the type of material being processed. The lens is further from the surface of the material reducing the chance the lens can become contaminated with residue.

4.0” Lens, this is one of the longest focal lens produced by APC - American Photonics. This lens is used when clearance or tolerance becomes an issue, and no shorter lens will work, this lens gives you an additional 2” (50,8mm) clearance over the standard 2.0” lens however the engraving detail is low due to its large spot size. This lens has the longest focal length and the best tolerance of any other lens kit offered making it excellent for cutting thick materials up to 1” (25,4mm) or more depending on the material.

What it does: The 4.0” inch lens produces a focused beam over a longer vertical distance, which makes it ideal when engraving within a recessed area of a product, such as inside a bowl or box. This is the best lens for thick, consistent straight edge cutting when clearance and tolerance is an issue. This lens is still able to mark and engrave though the quality is lower due to its large focus point size. This lens is much further from the surface of the material reducing the chance that this lens can become contaminated with residue

Please do not forget to check our mirrors for Boss laser here are the links of the most popular mirrors:

We are running a great promo pack of 3 mirrors for only $ 32 less expensive than chinese mirrors.

https://american-photonics.myshopify.com/collections/mark-and-engrave-co2-and-fiber-laser/products/silicon-mirror-3pcs-high-durability-coating-enhanced-99-7-reflection-co2-engraving-and-cutting-laser-40w-200w-quality-made-in-usa?variant=31593910370365

We offer Silicon Mirrors with silver Coating 99.7% with different diameters (19mm, 20mm, 25mm and 25.4mm) please check your machine to verify what is your mirror diameter.