Preserving Brilliance: How to Maintain and Protect Your Thin-Film Metallic Coated Mirrors

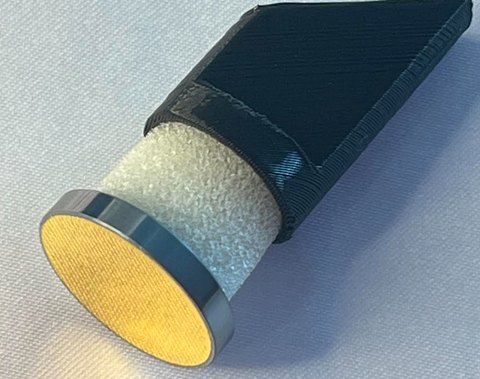

Introduction: Mirrors are indispensable in laser systems, serving as precision instruments that guide light beams for a multitude of applications, from high-power industrial cutting to delicate medical procedures. The secret to their functionality lies in their thin-film metallic coatings, often crafted from materials like silver or gold. These coatings are the driving force behind achieving maximum reflectivity and efficiency. In this article, we will explore thin-film metallic coated mirrors, highlight the advantages of silver coatings over gold, and provide essential tips for preserving their exceptional reflective properties. #ThinFilmMirrors #ReflectiveCoatings

The Significance of Thin-Film Metallic Coated Mirrors: Thin-film metallic coated mirrors are meticulously designed for laser systems, offering unmatched precision and reflectivity. Their significance cannot be overstated:

-

Exceptional Reflectivity: These mirrors feature specialized coatings tailored to laser wavelengths, minimizing energy loss during beam reflection, resulting in highly efficient laser operations. 💡🚀

-

Broad Wavelength Compatibility: Thin-film metallic coated mirrors are versatile, capable of performing across a wide spectrum of laser wavelengths, making them suitable for a range of laser applications. 🌈🔬

-

Superior Reflective Coatings: Unlike standard mirrors, thin-film metallic coated mirrors are optimized for reflectivity, delivering top-tier performance in laser setups. 🌟🔍

Silver vs. Gold Coatings: The Reflectivity Battle: The choice of coating material for thin-film metallic mirrors is pivotal, with two primary contenders: silver and gold. While both materials have their merits, silver coatings emerge as the preferred option for laser applications:

Silver Coating: Silver coatings excel, particularly in the near-infrared spectrum commonly used in lasers, ensuring minimal energy loss and optimal laser performance. This performance comes at a more budget-friendly price point, making silver-coated thin-film metallic mirrors an excellent choice for efficiency and cost-effectiveness. 💰🌌

Gold Coating: Gold coatings have been utilized for mirrors in the past, but they fall short of silver in terms of reflectivity, especially in laser-relevant wavelengths. While gold coatings have their applications, they may not deliver the efficiency required for high-performance laser systems. 🥇❌

Caring for Thin-Film Metallic Coated Mirrors: Preserving the reflective coating on thin-film metallic coated mirrors is crucial to maintain their performance. Here are essential care tips:

-

Gentle Cleaning: Use a soft, lint-free optical cleaning cloth or lens tissue to gently clean the mirror's surface, avoiding abrasive materials that can scratch or damage the coating. 🧼🧽

-

Cleaning Solutions: When cleaning is necessary, opt for specialized optical cleaning solutions or high-purity isopropyl alcohol (90% or higher). Apply the solution to the cleaning cloth, not directly onto the mirror. 💧🧴

-

Contaminant Prevention: Store mirrors in a clean, dust-free environment to prevent dust and dirt buildup. Handle mirrors with clean, dry hands or gloves to avoid transferring contaminants. 🧤🌬️

-

Regular Inspection: Periodically inspect mirrors for contaminants, scratches, or signs of coating damage. Address any issues promptly to ensure optimal performance. 🔍🔦

Protecting Your Thin-Film Metallic Coated Mirrors: Beware of Damaging Chemicals While thin-film metallic coated mirrors are essential for laser precision, their delicate coatings can be vulnerable to certain chemicals. Be cautious of these substances, as they can potentially harm the coating:

-

Ammonia-Based Cleaners: Many commercial glass cleaners contain ammonia, a compound that can gradually break down the mirror coating. Avoid using these cleaners for your thin-film metallic coated mirrors. 🚫🧴

-

Alcohol-Based Products: Some beauty and personal care products, such as hairspray and perfumes, contain alcohol. Overspray or direct contact with these products can lead to the deterioration of mirror coatings. 🌬️🚿

-

Acidic Substances: Acidic cleaners or substances like vinegar can corrode the coating over time. Exercise caution when using any acidic solutions near your mirrors. ⚗️🧪

-

Hard Water Stains: In areas with hard water, water spots can form on the mirror's surface over time, potentially weakening the coating if left untreated. 💧🌧️

By being mindful of these potentially damaging chemicals and following proper care practices, you can ensure the longevity and continued optimal performance of your thin-film metallic coated mirrors. 🛡️🔬

Silver Coating Advantage: Silver-coated thin-film metallic mirrors provide unmatched reflectivity in laser applications, particularly in the near-infrared spectrum. Their superior performance and cost-effectiveness make them the preferred choice for high-performance laser systems. 🌌💎

Conclusion: Thin-film metallic coated mirrors are indispensable components in laser systems, offering exceptional reflectivity and precision. Choosing the right coatings, such as silver, is essential for maximizing laser efficiency. By following proper care practices, you can prolong the lifespan and maintain the peak performance of your thin-film metallic coated mirrors. Trust in American Photonics for mirrors that reflect not only quality but also your commitment to laser excellence. Explore our range of thin-film metallic coated mirrors, featuring silver coatings for superior laser performance and efficiency. 🔍🔬 #LaserMirrors #SilverCoating #ReflectiveCoating

Here are a few mirror options you can find in American Photonics' inventory:

Silicon Si Mirror 20mm (3pc) High Durability 99.7% Coating Co2 Laser

Silicon Si Mirror 25mm (3pc) High Durability 99.7% Coating Co2 Laser

Glowforge(R) Printer Head Mirror 100% made in the USA