ZnSe Focus Lens – Dia. 1.5" (38.1 mm), FL 7.5" (190.5 mm), ET 0.291" (7.4 mm) – Compatible with Trumpf® CO₂ Laser (Ref. PN 97517)

ZnSe Focus Lens – Dia. 1.5" (38.1 mm), FL 7.5" (190.5 mm), ET 0.291" (7.4 mm) – Compatible with Trumpf® CO₂ Laser (Ref. PN 97517) ist auf Lager und wird versandt, sobald es wieder verfügbar ist

Care information

Care information

High care information about CO2 laser lenses, fiber laser protective windows, and

fiber laser lenses is essential to ensure the optimal performance and longevity

of these critical components in laser systems. Here are some key points to consider:

CO2 Laser Lenses:

Cleaning:

Regularly clean CO2 laser lenses to remove dust, debris, and residue. Use a

soft, lint-free cloth or lens cleaning tissue. Avoid using abrasive materials

that may scratch the lens.

Handling:

Always handle CO2 lenses with clean hands or lint-free gloves to avoid transferring oils or contaminants onto the lens surface.

Storage:

Store lenses in a clean, dry, and dust-free environment to prevent damage and

maintain their integrity.

Alignment:

Properly align CO2 lenses within the laser system to ensure efficient laser

beam delivery and focus.

Inspection:

Regularly inspect lenses for signs of damage, scratches, or deterioration.

Replace any damaged or worn lenses promptly.

Fiber

Laser Protective Windows:

Cleaning:

Clean fiber laser protective windows with care to avoid scratches. Use a gentle

cleaning solution and a soft, lint-free cloth.

Protection:

Keep protective windows in place when the laser system is not in use to prevent

contamination and damage.

Replacement:

If protective windows become damaged, replace them immediately to maintain

laser system safety and performance.

Fiber Laser Lenses:

Cleaning:

Clean fiber laser lenses carefully to prevent damage. Use a lens cleaning

solution and a soft, lint-free cloth or lens tissue.

Handling:

Handle fiber laser lenses with care to avoid fingerprints, oils, or scratches

on the lens surface.

Alignment:

Properly align fiber laser lenses to ensure accurate laser beam focusing and

efficient performance.

Inspection:

Regularly inspect fiber laser lenses for signs of wear, damage, or contamination. Replace any compromised lenses promptly.

Environmental Considerations: Be mindful of environmental factors such as temperature and

humidity, as extreme conditions may affect lens performance.

Overall,

maintaining high care and attention to detail when handling, cleaning, and

storing CO2 laser lenses, fiber laser protective windows, and fiber laser

lenses will enhance their longevity and contribute to the smooth and reliable

operation of your laser systems. Always follow the manufacturer's guidelines

and best practices for each specific component to ensure optimal results.

Delivery and Shipping

Delivery and Shipping

FOR ITEMS IN STOCK:

Orders placed before 2:00 pm EST/EDT on a business day

(Monday - Friday) will ship the same day.

Orders placed after 2:00 pm EST/EDT may not be be shipped

until the next business day.

Our business hours are Monday to Friday, 9 am-4:30 pm.

Orders placed after business hours will not be processed

until the next business day.

Orders placed during the weekend (Saturday - Sunday) or

holiday will be shipped on the next business day.

All packages are shipped FOB ORIGIN – These shipping terms

are characteristic of a “SHIPMENT CONTRACT” and the seller bears the expense

and risk of putting the goods in the possession of the carrier. Title transfers to the buyer at the point when the goods leave the shipper’s loading dock but reverts back to the seller if the buyer follows the correct procedures of notifying the seller of “breach” by “rightfully revoking cceptance.” Even if “breach” has occurred, the buyer remains responsible for filing “carrier loss

claims.”

ZnSe Focus Lens 1.5" (38.1 mm) Dia × 7.5" (190.5 mm) FL – Trumpf® CO₂ Laser Compatible | ET 0.291" (7.4 mm) | Ref. PN 97517

Precision ZnSe Focus Lens for Trumpf® CO₂ Laser Systems

This ZnSe (Zinc Selenide) focus lens is engineered for industrial CO₂ laser cutting applications, providing high transmission at 10.6 µm, reliable beam focus, and consistent cutting performance. Manufactured to precise dimensional tolerances, this lens is a direct-fit compatible replacement for Trumpf® CO₂ laser optics (Ref. PN 97517).

Designed for demanding production environments, the lens delivers stable focal performance and dependable thermal behavior under standard operating conditions, helping maintain cut quality and process repeatability. It is well suited for CO₂ laser cutting of metals and non-metal materials such as acrylics and plastics, as well as general industrial laser processing applications where a 7.5" focal length is specified.

Technical Specifications

| Specification | Details |

|---|---|

| Material | Laser-grade ZnSe (Zinc Selenide) |

| Diameter | 1.5" (38.1 mm) |

| Focal Length (FL) | 7.5" (190.5 mm) |

| Edge Thickness (ET) | 0.291" (7.4 mm) |

| AR Coating | Anti-Reflective optimized for 10.6 µm |

| Laser Type | CO₂ |

| Wavelength | 10.6 µm |

| Absorption | < 0.15 % |

| Shape | Circular |

| Tolerances | Tight optical & dimensional tolerances |

| Application | CO₂ laser cutting optics |

Note: This ZnSe lens is designed for CO₂ laser wavelengths (10.6 µm) — not suitable for fiber laser wavelengths.

Available Options

| APC Part Numbers | OEM & Reference Part Numbers |

|

LM-38.1-Z-190.5-7.40-AR Legacy part#: ZM15750291 |

97517, 0097517,097517, 60697, 702232, 110110, 61983, 29100030, TR300-7517, HG10.168/H, RLT101/75S |

Typical Applications

- CO₂ Laser cutting of mild steel, stainless steel, aluminum

- High-precision sheet metal fabrication

- Industrial laser maintenance and service replacements

- OEM-compatible lens refurbishment cycles

- Production environments requiring consistent focus quality

Features & Benefits

Features

- Precision AR coating optimized for long CO₂ wavelengths

- Low laser absorption (< 0.15 %) for reduced thermal stress

- Manufactured with high consistency using automated CNC

- Designed for compatibility with Trumpf® CO₂ cutting heads

- Wide set of cross-reference part numbers for easier system matching

Benefits

- Improved Laser Performance: Better power throughput and focus stability

- Reliable Replacement: Drop-in compatibility with common Trumpf® optics

- Long Service Life: Low absorption and precise tolerances reduce wear

- Made in USA: High quality assurance and domestic manufacturing

- Ease of Maintenance: Compatible with existing machine maintenance workflows

Compatibility

Compatible with Trumpf® CO₂ laser cutting machines that use a 1.5" diameter, 7.5" focal length focus lens design. Common compatible systems include:

- TruLaser® Series 1000

- TruLaser® Series 2000 / 3000 (square cutting head)

- TruLaser® Series 5000 (square cutting head)

- TruLaser® Tube Series 3000 / 5000

- TruMatic® Series 3000 / 6000

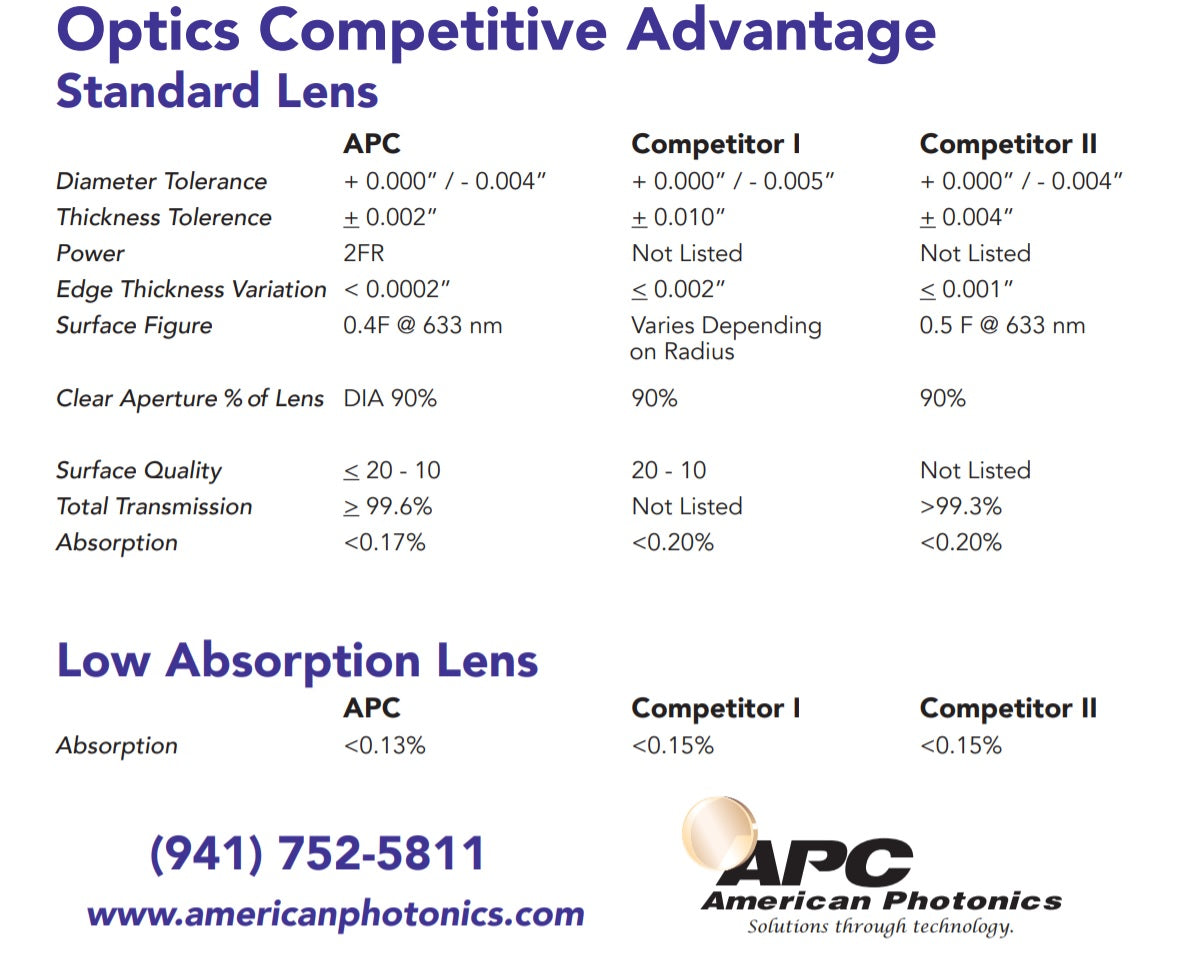

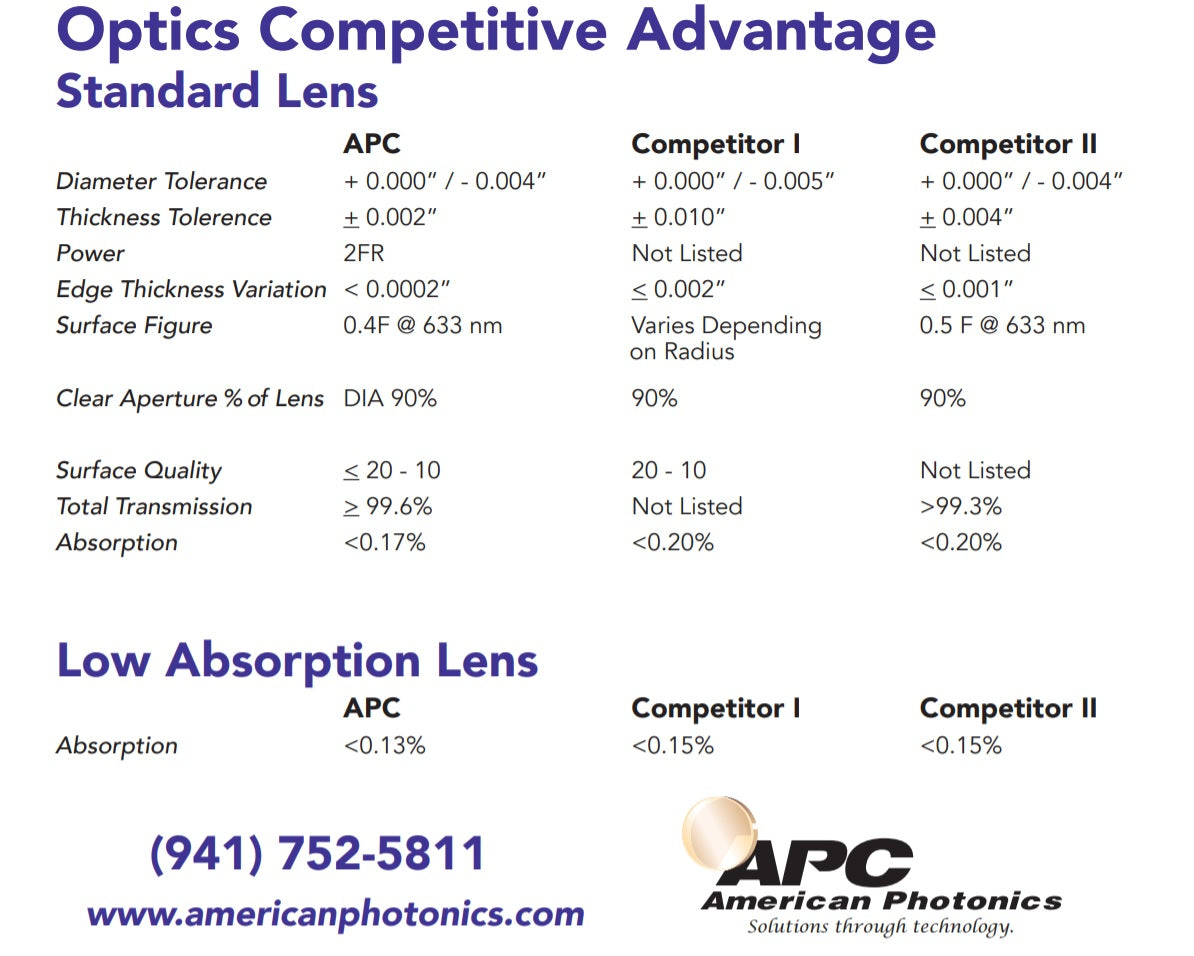

APC Specification Table

| Specification | APC Guaranteed Value |

|---|---|

| Effective Focal Length (EFL) Tolerance | ±1% |

| Diameter Tolerance | +0 / −0.004" |

| Thickness Tolerance | ±0.002" |

| Edge Thickness Variation (ETV) | ≤ 0.0002" |

| Clear Aperture (Polished) | ≥ 90% of diameter |

| Scratch-Dig | ≤ 20-10 |

| AR Coating Reflectivity (per surface @ 10.6 µm) | < 0.1% |

Note: Not for use with fiber lasers or non-CO₂ laser systems.

FAQs

Q: Is this ZnSe lens compatible with fiber lasers?

A: No — ZnSe optics are optimized for CO₂ laser wavelengths (~10.6 μm) and are not suitable for fiber laser wavelengths.

Q: Does this part replace Trumpf® OEM 97517?

A: Yes. This APC focus lens is designed as a compatible replacement for OEM 97517 and related cross-reference numbers.

Q: What does “ET” mean?

A: ET refers to edge thickness, the thickness of the lens at its rim, which affects mounting fit and optical performance.

Q: Why choose American Photonics optics?

A: Engineered with tighter tolerances and low absorption, APC optics help maintain consistent laser performance while providing a cost-effective alternative to OEM parts.

Q: How should I handle and care for this lens?

A: Handle only with clean, lint-free gloves and store in a clean, dry environment to prevent contamination and preserve optical quality.

APC replacements parts are approved by many OEMs.

To be used on HPed Co2 Laser cutting machines.

Manufactured by automated CNC technology 100% made in USA.

Disclaimer: All parts advertised for sale are made by or for American Photonics.

Amada(R), Bystronic(R), Cincinnati(R), Mazak(R), Mitsubishi(R), Laserlab(R) Laserdyne Prima(R), Precitec(R), Strippit(R), Trumpf(R) and any other trademarks not owned by APC are registered trademarks of the respective owners with which they are associated. APC is an independent site and company that is not affiliated with above-named manufacturers and the use of the names, trademarks and part numbers is for reference, identification and compatibility purposes only.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

KeyFeatures of Our Products: