Title: 🌟 Elevating High-Power Laser Systems: Comprehensive Guide to Optimal Cutting Quality 🚀

Category: #HighPowerLaserSystems #LaserCuttingExcellence #AmericanPhotonicsInsights

Hello and welcome back to the American Photonics blog! As an optics manufacturer specializing in high-quality lenses and accessories for CO2 and Fiber Laser Systems, we're always exploring ways to enhance the performance of laser cutting equipment. While we're not specialized in laser systems themselves, we've investigated key factors in laser cutting and believe this information will be beneficial to our clients. Remember, for the best focusing lenses, nozzles, ceramic nozzle holders, and more, equal or superior to OEM quality, American Photonics is your go-to source: www.americanphotonics.com.

Delving Deep into High-Power Laser Cutting

High-power laser cutting, featuring brands like Trumpf(R), Amada(R), and Precitec (R), is a field that combines precision engineering with the nuanced interplay of various technical elements. Achieving optimal cut quality is not just a matter of using high-end equipment but also understanding the intricacies of the cutting process.

Understanding and Optimizing Cut Quality

Achieving the ideal cut involves a blend of technical know-how and precise adjustments. Let's explore the key steps and strategies:

Starting with Known Settings: Using familiar settings for your material is crucial.

Testing with Purpose: Test parts with both interior and exterior features provide a comprehensive quality assessment.

Lens and Window Maintenance: Ensuring your optics are in top condition is vital.

Nozzle Condition and Alignment: A well-maintained and correctly aligned nozzle can significantly impact cut quality.

The Role of Gas Dynamics in Laser Cutting

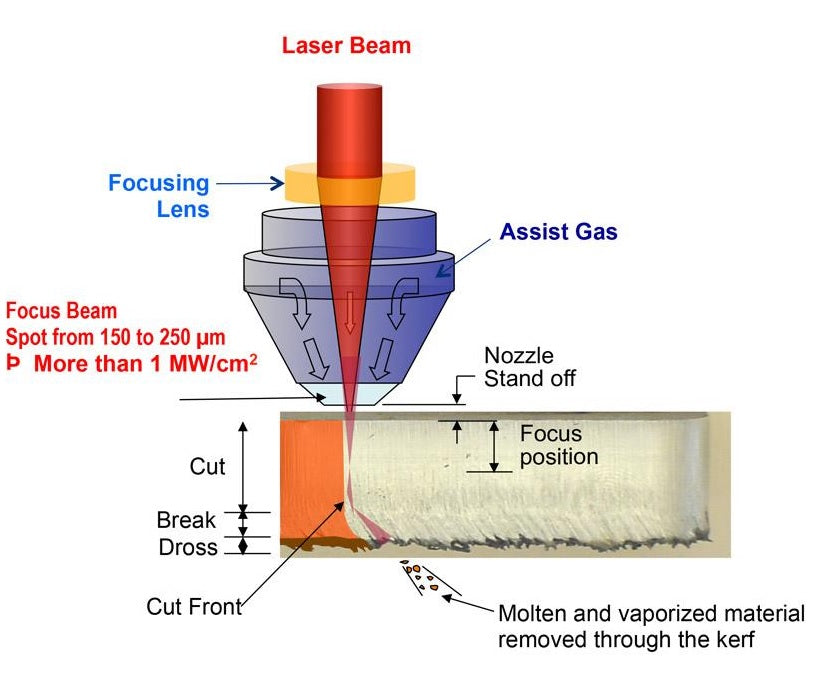

Gas flow dynamics play a critical role in the cutting process. The interaction between the laser beam, assist gas, and workpiece is key to creating that perfect cut edge. This involves balancing factors like nozzle diameter and gas pressure.

Balancing Nozzle Diameter and Gas Pressure

The smallest nozzle diameter that achieves the desired quality should be used to control the gas flow rate. Gas pressure should be high enough for a clean cut but controlled to avoid unnecessary costs.

Standoff Distance and Cutting Speed

Standoff distance typically equals the nozzle diameter and impacts molten metal evacuation. Contrary to intuition, a slower cutting speed can lead to more burrs due to increased heat.

Special Considerations for Oxygen Cutting

Oxygen purity levels significantly impact cutting speeds in carbon steel. The purity of the oxygen affects the exothermic reaction and, consequently, the cutting performance.

Addressing Ambient Air Effects

Ambient air temperature can impact gas flow dynamics, making it crucial for operators to adjust their settings based on these environmental factors.

Achieving a Burr-Free Cut

A burr-free cut requires ensuring that the beam parameters and gas dynamics work in harmony. Attention to details like nozzle cleanliness, gas pressure, and cutting speed can dramatically improve cut quality.

Advanced Techniques for Burr-Free Laser Cutting in High-Power Systems

Insights into Gas Dynamics and Laser Interaction

Understanding the intricate interaction of the laser beam, assist gas, and material is critical. This includes knowing which laser parameters to change, such as beam alignment, nozzle centering, and focus position.

What Creates the Burr?

Burrs are created when molten metal solidifies faster than it can be evacuated. This can be influenced by the dynamic action of the assist gas and the intensity of the laser beam. When cutting with nitrogen, an inert gas, the process relies solely on the beam's energy to melt the metal. In contrast, oxygen cutting with carbon steel involves an exothermic reaction, adding heat and requiring less gas pressure.

Gas Dynamics in Laser Cutting

Controlling nitrogen assist gas consumption is vital, as it can comprise a significant portion of the variable costs in laser cutting. Optimal cutting parameters aim to minimize nozzle diameter and adjust gas pressure to the lowest necessary level for a quality cut.

The Subtle Science of Burr-Free Laser Cutting

Slower Doesn’t Mean Better

The misconception that slower cutting speeds result in fewer burrs is common. However, this can inject more heat than needed into the kerf, causing vaporization that disturbs gas flow and leads to more burrs.

Oxygen Cutting Considerations

With oxygen cutting for carbon steel, the purity level of the oxygen plays a critical role. Higher oxygen purity levels, typically above 99.95%, can significantly increase cutting speeds.

Don’t Forget the Plumbing When Laser Cutting

Gas plumbing in the laser cutting system, such as avoiding elbows in the piping and purging the atmosphere in the pipe during downtime, can significantly impact cutting performance.

American Photonics Optics are manufactured by automated CNC technology 100% made in USA.

Disclaimer: All parts advertised for sale are made by or for American Photonics.

Amada(R), Bystronic(R), Cincinnati(R), Mazak(R), Mitsubishi(R), Laserlab(R) Laserdyne Prima(R), Precitec(R), Strippit(R), Trumpf(R) and any other trademarks not owned by APC are registered trademarks of the respective owners with which they are associated. APC is an independent site and company that is not affiliated with above-named manufacturers and the use of the names, trademarks and part numbers is for reference, identification and compatibility purposes only.